Cheese Moulding Dosing Machines

FIBOSA’s innovative range of DOSIMATIC moulding dosing machines is characterised by unifying, in the same machine, systems for the production of open and/or closed type cheeses; soft, semi-hard and hard consistency cheeses. Our equipment saves space and handling, increasing flexibility and production capacity and achieving optimum homogeneity of the final product, adapting to each customer.

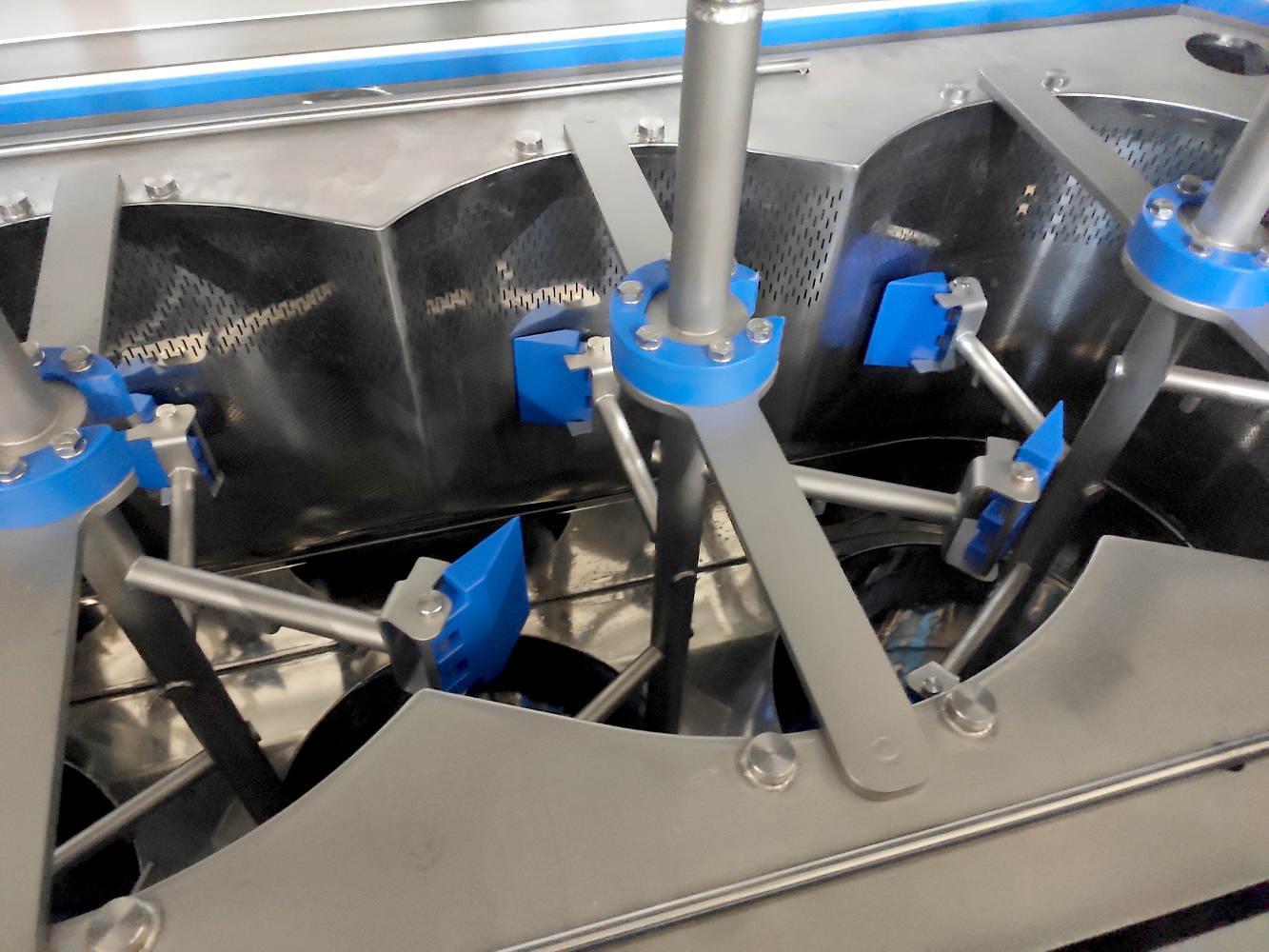

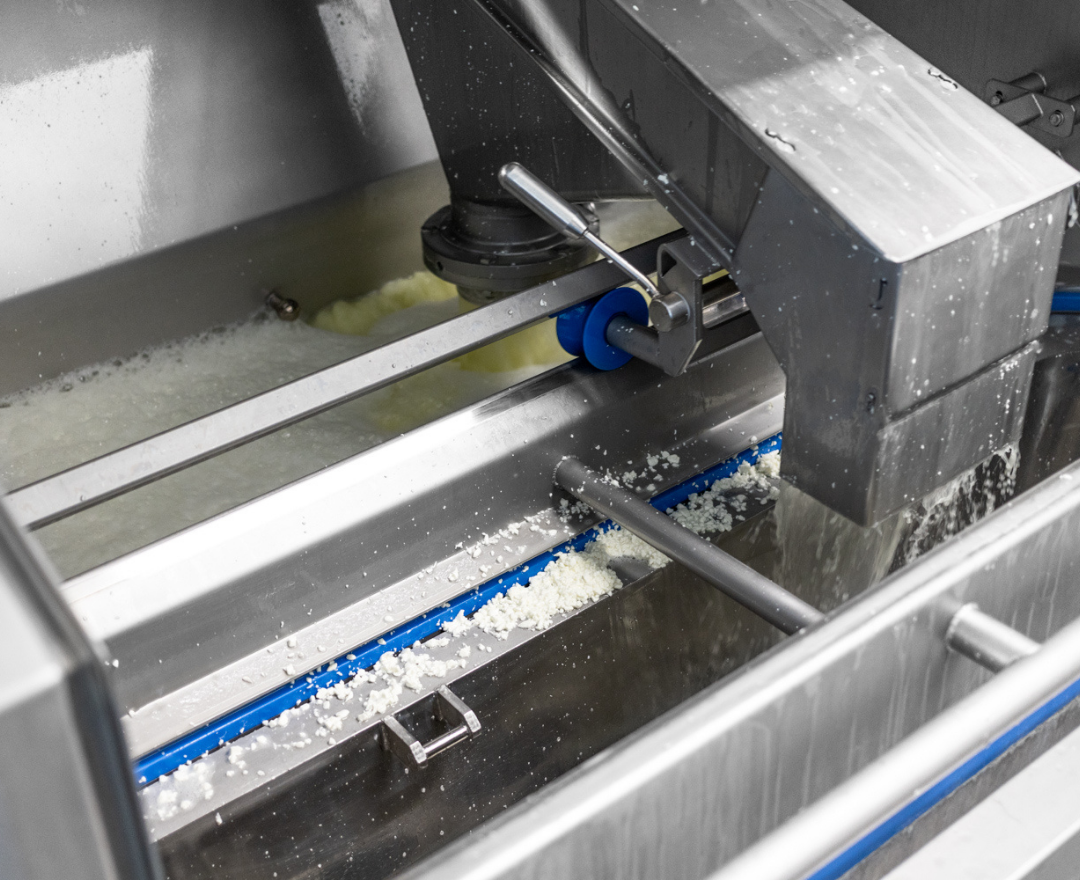

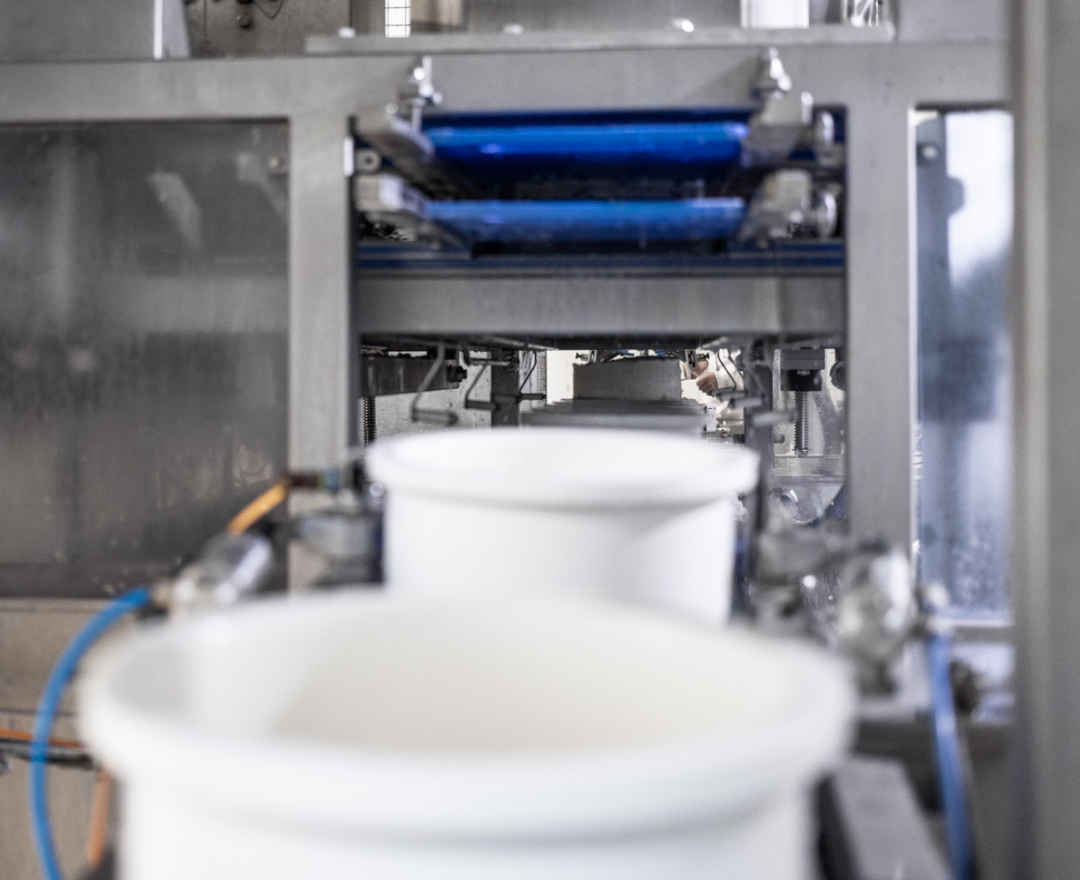

The FIBOSA moulding dosing machine is made up of three main independent modules for the different phases of treatment, moulding and dosing. The upper curd distribution unit incorporates filtering and agitation mechanisms for the draining process. The intermediate module, or cassette, brings together a set of uniquely designed micro-perforated columns and independent whey levels to achieve a level of draining and pre-pressing adapted to each type of product. The lower module is made up of reinforced and easily interchangeable shapers, which can be automatically adjusted to produce cheeses of different heights, and a set of high-precision cutting blades.

Our dosing machines incorporate a conveyor set, control and regulation of parameters and processes by means of a programmable automaton and touch screen and are adapted to the CIP cleaning system.

It is complemented with the washing cabinet for the set of columns and accessories; the hoist for the extraction of the set of columns and the access platform.

Models

PLUS

The perfect solution for the production of open-curd cheeses. This model stands out for its totally enclosed structure, which ensures optimal automatic cleaning. It incorporates a multi-level draining cassette and an adjustable moulder to adapt to different production needs.

UNIVERSAL

Maximum versatility in a single machine, suitable for the production of open and closed curd cheeses. It offers a closed structure that guarantees efficient automatic cleaning, a multi-level draining cassette and an adjustable moulder that adapts to a wide variety of formats.Models

PLUS

The perfect solution for the production of open-curd cheeses. This model stands out for its totally enclosed structure, which ensures optimal automatic cleaning. It incorporates a multi-level draining cassette and an adjustable moulder to adapt to different production needs.